Extend the life of your assets with our planned preventive maintenance software

Proactive care for peak performance.

Unlock peak performance

Keep operations aligned and efficient with PPM.

Prevent Costly Downtime

Maintenance delays can cost businesses up to $260k per hour. Proactive scheduling keeps your equipment—and profits—running smoothly.

Maximize Asset Lifespan

80% of assets fail prematurely due to inconsistent maintenance. mpro5 streamlines PPM, extending the life of your critical equipment.

Cut Maintenance Costs

Reactive maintenance costs 3x more than planned maintenance. Transition to a preventive approach and significantly reduce expenses.

Automate Preventative Maintenance Scheduling

Simplify and streamline your maintenance routine.

Learn More

Implement automated scheduling for planned preventative maintenance (PPM) tasks to reduce manual intervention and ensure all maintenance activities are carried out on time. By automating PPM scheduling, you’ll reduce downtime, extend equipment life, and allow your team to focus on more strategic tasks.

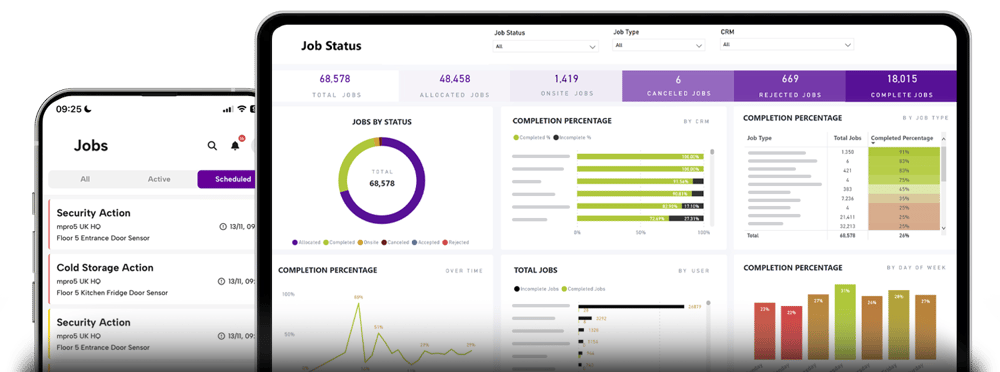

Make Informed, Data-Driven Decisions

Leverage insights from real-time data to avoid costly breakdowns.

Learn More

Proactively manage your maintenance schedule using data analytics to predict issues before they arise. By analyzing performance trends, you can make informed decisions, adjust schedules, and take corrective actions before minor issues become major problems, reducing unplanned downtime and repair costs.

Gain Visibility into Asset Performance and Costs

Track the true cost of your assets and make informed decisions.

Learn More

With real-time asset tracking, you can easily monitor the performance, maintenance, and overall cost of each asset in your organization. By understanding the total cost of ownership—including acquisition, maintenance, repairs, and energy consumption—you can make data-driven decisions that optimize asset utilization, reduce inefficiencies, and improve long-term budgeting. This visibility ensures you're investing wisely in assets that deliver the greatest return on investment (ROI) while minimizing hidden costs.

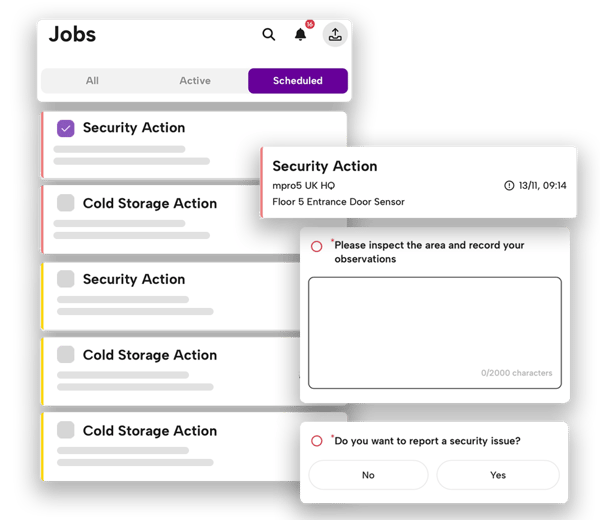

Digitize and Optimize Maintenance Workflows

Eliminate the inefficiencies of paper-based processes.

Learn More![]() Move away from paper records and adopt a digital PPM solution. With centralized, easily accessible data, you can track maintenance activities in real-time, reduce errors, and enhance accountability across your team. This allows you to stay on top of scheduled tasks and improve overall workflow efficiency.

Move away from paper records and adopt a digital PPM solution. With centralized, easily accessible data, you can track maintenance activities in real-time, reduce errors, and enhance accountability across your team. This allows you to stay on top of scheduled tasks and improve overall workflow efficiency.

Start streamlining your processes today!

Complete the short form below and we'll be in touch soon!

43%

UK supermarkets using mpro5

140+

Million work orders completed

175+

Million jobs created

Explore All of our FM Solutions:

Select an option below:

- CMMS

- CAFM

- EHS

- Regulatory Compliance

- EAM

- Operations Management

- Transportation Management

CMMS

Simplify maintenance and reduce downtime with our customized CMMS. Take control of maintenance tasks with a streamlined approach.

CAFM

Simplify facility management with our flexible CAFM solutions. Gain complete control over assets, spaces, and maintenance with one unified system.

EAM

Take charge of asset lifecycle management with our EAM app. Boost productivity and performance with intelligent tracking.

Operations Management

Simplify operations management with our process management app. Drive efficiency and coordination across your business.

Transportation Management

Revolutionize fleet operations and streamline logistics for cost-effective, efficient journeys.

Frequently Asked Questions

Find answers to common questions we receive.

-

What is PPM?

Planned Preventative Maintenance (PPM) refers to the proactive approach of scheduling regular, routine maintenance tasks to prevent equipment breakdowns and extend asset lifespan. PPM helps ensure that all systems and machinery operate efficiently, reducing the likelihood of unexpected failures and costly repairs.

-

What are the benefits of Planned Preventative Maintenance (PPM)?

Implementing PPM in your organization provides several key benefits:

- Reduced Downtime: By identifying and addressing potential issues before they occur, PPM reduces unexpected breakdowns and unplanned downtime.

- Extended Equipment Lifespan: Regular maintenance ensures your assets run smoothly and last longer, improving return on investment.

- Cost Savings: Preventing major equipment failures through routine maintenance reduces repair costs and helps avoid expensive emergency repairs.

- Improved Safety and Compliance: PPM ensures that all equipment meets safety and compliance standards, reducing the risk of workplace accidents and regulatory fines.

-

How does PPM work in maintenance?

In maintenance management, PPM is used to plan, schedule, and perform maintenance tasks on equipment or facilities before they fail. This often includes regular checks, inspections, and replacements of parts to ensure the asset operates optimally. By setting up a PPM schedule, businesses can reduce the frequency of major breakdowns, enhance the lifespan of their assets, and improve overall operational efficiency.

-

How can PPM benefit my business?

Adopting a PPM strategy can bring substantial benefits to your business:

- Increased Efficiency: Automating and scheduling maintenance tasks ensures that all equipment is properly maintained without the need for last-minute rushes.

- Cost Reductions: By addressing issues proactively, you can avoid costly repairs and replace parts at the right time to prevent sudden failures.

- Better Resource Allocation: With automated scheduling, your team can focus on high-priority tasks, optimizing time and resources.

- Enhanced Asset Reliability: PPM helps maintain equipment at peak performance, minimizing the risk of failure and extending the life of expensive machinery.

With solutions like mpro5, you can take your PPM strategy to the next level by integrating real-time data, creating custom workflows, and ensuring that your maintenance schedule adapts to changing operational needs.

-

Is mpro5 a Planned Preventative Maintenance solution?

While mpro5 isn’t a traditional PPM software, it provides powerful tools to help manage and automate your preventative maintenance schedules.

- mpro5 enables you to track maintenance tasks, automate scheduling, and monitor asset health in real-time.

- Its flexible platform allows you to customize maintenance workflows, integrate IoT sensors for predictive maintenance, and ensure compliance with safety regulations.

With mpro5, you can optimize your PPM processes and reduce the risk of unexpected downtime and costly repairs.

Our latest insights:

3 min read

Could superglue be the cure for your subcontractor pain?

Nov 4, 2024 by Konnor Baskaran

2 min read

Compliance Management Across Multi-Site Businesses: The Challenges & Solutions

Oct 24, 2024 by Konnor Baskaran