Protect your people and your business with comprehensive OHS software

Ensure compliance and foster a safer, more productive environment.

%20Graphic.png?width=600&height=467&name=Occupational%20Health%20%26%20Safety%20(OHS)%20Graphic.png)

Minimize Workplace Injuries

Proactively manage operational health and safety to ensure a safer, more compliant workplace.

Prevent Injuries

With workplace injuries costing employers up to $41,000 per incident, prevent accidents before they occur by streamlining safety protocols and compliance tracking.

Document Safety Compliance

mpro5's real-time reporting and digital forms create an audit trail, helping you maintain compliance and defend against false claims, keeping your safety records airtight.

Reduce Lost Time

Workplace accidents lead to an average of 27 days of lost productivity. Mitigate downtime by ensuring faster response times to incidents and maintaining a safer environment.

Automate Compliance and Reporting

Reduce manual tracking and ensure consistent compliance with automated processes.

Learn More

Automate routine health and safety tasks like incident reporting, audits, and inspections to ensure timely and accurate documentation. This reduces the need for manual intervention, minimizes human error, and ensures your organization is always in compliance with local and global health and safety regulations.

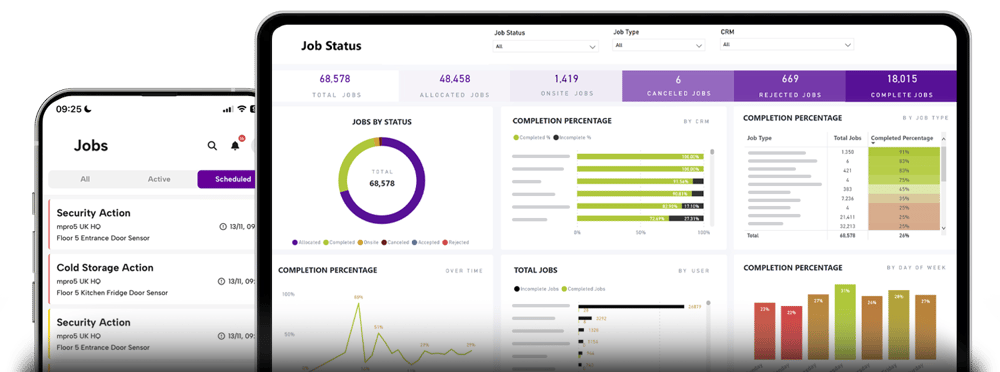

Automate routine health and safety tasks like incident reporting, audits, and inspections to ensure timely and accurate documentation. This reduces the need for manual intervention, minimizes human error, and ensures your organization is always in compliance with local and global health and safety regulations.Gain Real-Time Safety Insights

Monitor your safety protocols with real-time data to identify and address potential hazards.

Learn More

Leverage advanced data analytics to gain insights into your safety performance. Real-time tracking of incidents, hazards, and near-misses helps you identify patterns, preventing future risks and optimizing your safety programs. By proactively addressing risks, you can create a safer workplace and reduce the likelihood of accidents or regulatory penalties.

Leverage advanced data analytics to gain insights into your safety performance. Real-time tracking of incidents, hazards, and near-misses helps you identify patterns, preventing future risks and optimizing your safety programs. By proactively addressing risks, you can create a safer workplace and reduce the likelihood of accidents or regulatory penalties.Centralize Safety Communication and Collaboration

Ensure all employees and stakeholders are aligned with safety protocols and procedures.

Learn More

Centralize communication around OHS, ensuring that safety updates, reports, and training materials are easily accessible to all employees. A unified platform allows for clear, efficient communication, ensuring everyone stays informed and can collaborate effectively to reduce workplace risks.

Centralize communication around OHS, ensuring that safety updates, reports, and training materials are easily accessible to all employees. A unified platform allows for clear, efficient communication, ensuring everyone stays informed and can collaborate effectively to reduce workplace risks.Digitize Safety Management Processes

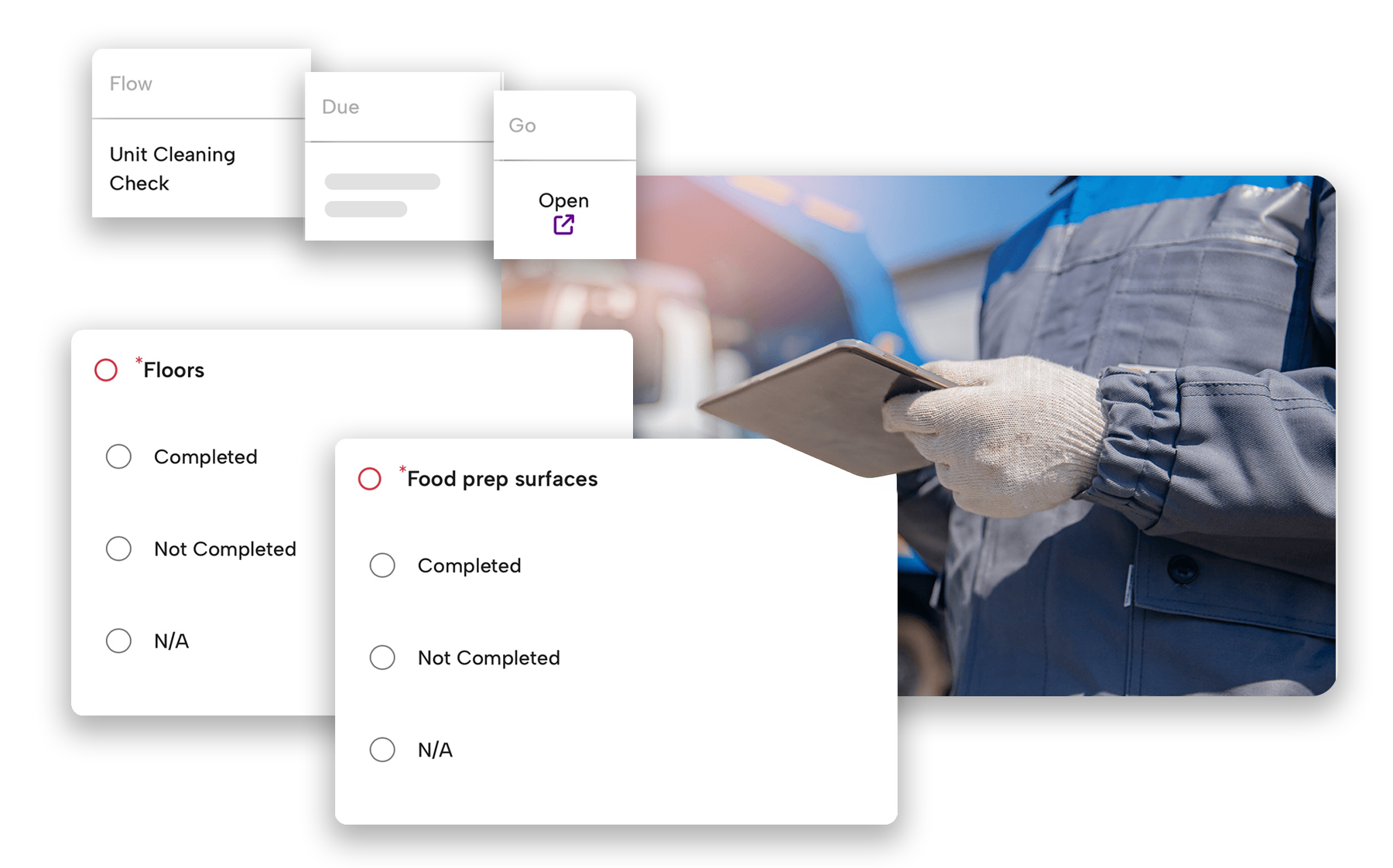

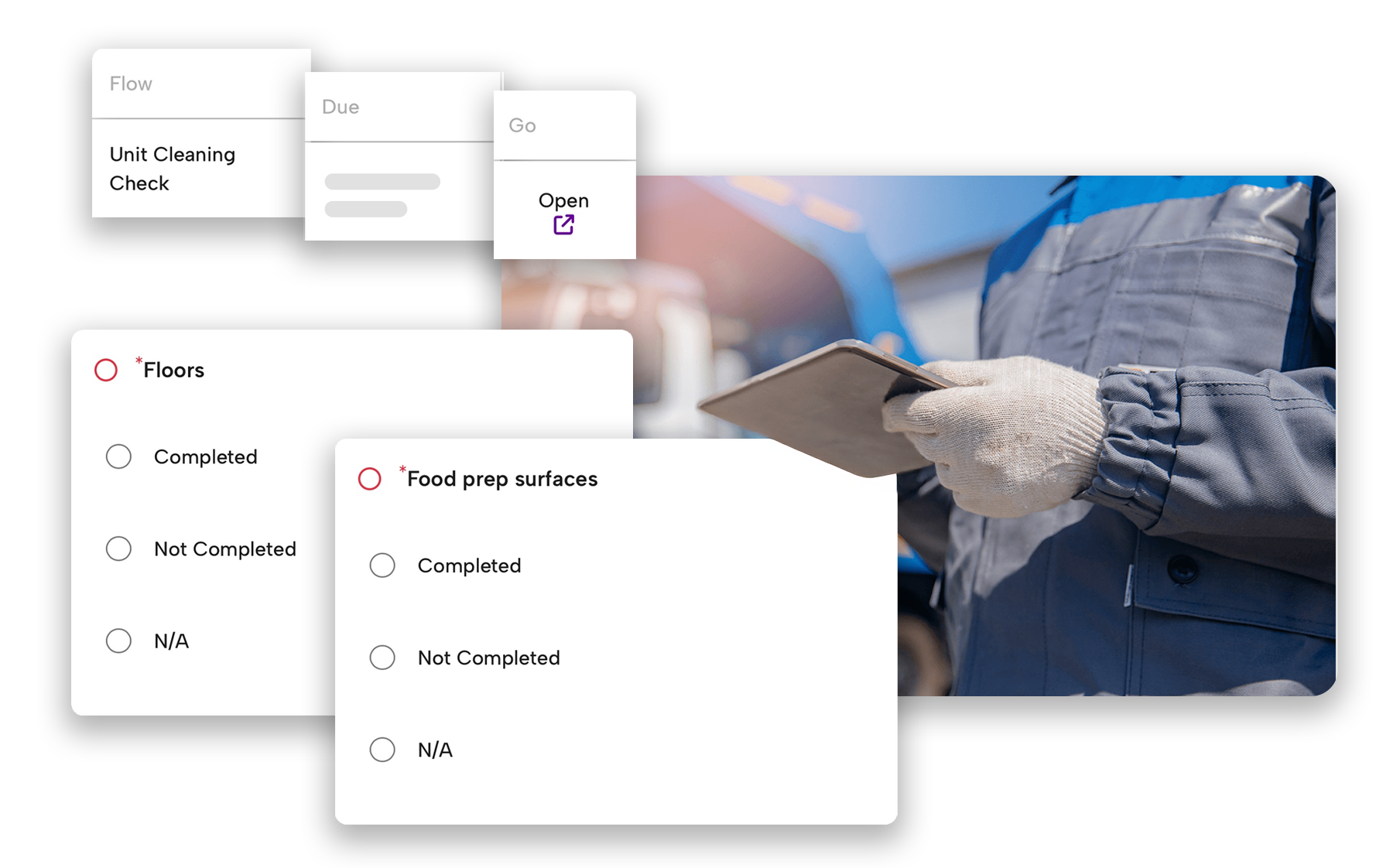

Transition from paper-based OHS processes to a more efficient digital solution.

Learn More

Eliminate paper-based safety records and embrace a fully digital system for managing incident reports, safety inspections, and compliance documents. Digitizing OHS processes reduces the risk of lost or outdated records and ensures that critical information is always accessible when needed, improving accuracy and reducing administrative overhead.

Eliminate paper-based safety records and embrace a fully digital system for managing incident reports, safety inspections, and compliance documents. Digitizing OHS processes reduces the risk of lost or outdated records and ensures that critical information is always accessible when needed, improving accuracy and reducing administrative overhead.

Start streamlining your processes today!

Complete the short form below and we'll be in touch soon!

43%

UK supermarkets using mpro5

140+

Million work orders completed

175+

Million jobs created

Select an option below:

- HACCP

- QMS

- Food Safety Management

- Compliance

- Food Traceability

- Temperature Checks

- Operations Management

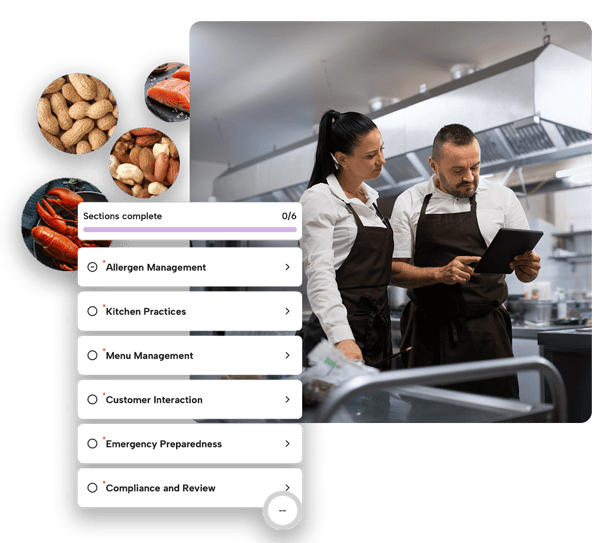

HACCP

Take the risk out of food safety with digitized HACCP planning. Proactively identify, prevent, and control potential hazards.

QMS

Enhance quality management with our integrated QMS solutions. Drive consistency and continuous improvement across operations.

Food Traceability

Boost confidence in your supply chain with food traceability software. Track and verify every step and product, from source to sale.

Temperature Checks

Streamline temperature monitoring for safety and compliance. Eliminate risks with automated, real-time automated logging.

Operations Management

Transform operations management with mpro5's intuitive solutions. Streamline workflows and drive operational excellence across your organization.

Frequently Asked Questions

Find answers to common questions we receive.

-

What is Occupational Health and Safety (OHS)?

Occupational Health and Safety (OHS) refers to the practices and regulations aimed at ensuring the safety, health, and well-being of employees in the workplace. OHS management involves identifying hazards, mitigating risks, and ensuring compliance with safety standards to prevent workplace accidents and injuries.

-

Why is OHS important in the workplace?

Occupational Health and Safety (OHS) is essential in the workplace because it helps prevent injuries, illnesses, and fatalities. A strong OHS program not only ensures compliance with health and safety regulations but also improves employee well-being, boosts productivity, and reduces operational costs by minimizing workplace accidents and related liabilities.

-

What are the key components of an effective OHS management system?

An effective OHS management system includes components like hazard identification, risk assessment, safety training, emergency preparedness, incident reporting, and compliance monitoring. It ensures that health and safety risks are managed proactively and that employees are educated about safety practices, creating a safer and more productive workplace.

-

How does OHS software improve workplace safety?

OHS software enhances workplace safety by streamlining incident reporting, tracking hazards, automating compliance, and improving safety communication. It allows organizations to monitor real-time safety data, respond quickly to incidents, and ensure employees are always informed about safety protocols, reducing the risk of accidents and injuries.

-

How can OHS software reduce workplace accidents?

OHS software reduces workplace accidents by providing tools for identifying potential hazards, tracking safety performance, and ensuring that employees adhere to safety protocols. The software enables proactive risk management, helping to mitigate the likelihood of accidents before they occur by highlighting areas that need attention and improvement.

Our latest insights:

2 min read

Automate your way to sustainability reporting success in 2025

Dec 30, 2024 by Fred Whipp

3 min read

Ensuring Compliance in the Food Industry: Strategies for Channel Partners and Industry Leaders

Dec 6, 2024 by Matt Smith

%20Graphic.png?width=288&height=165&name=Quality%20Management%20(QMS)%20Graphic.png)