Take the risk out of food safety with digitized HACCP planning

Proactively identify, prevent, and control potential hazards.

Ensure Food Safety Compliance

Maintain HACCP standards, reduce risks and improve safety protocols.

Prevent Contamination

With foodborne illness outbreaks costing the food industry over $15.6 billion annually, safeguard your operations and reputation by meeting all HACCP regulations.

Track Critical Control Points

Track and monitor critical control points in real-time, guaranteeing your organization stays compliant and proactive in food safety management.

Reduce Recalls

Food recalls cost the food industry an average of $10 million per incident. Minimize your risks with digital tools that streamline traceability and reporting, ensuring a swift response to any potential threats.

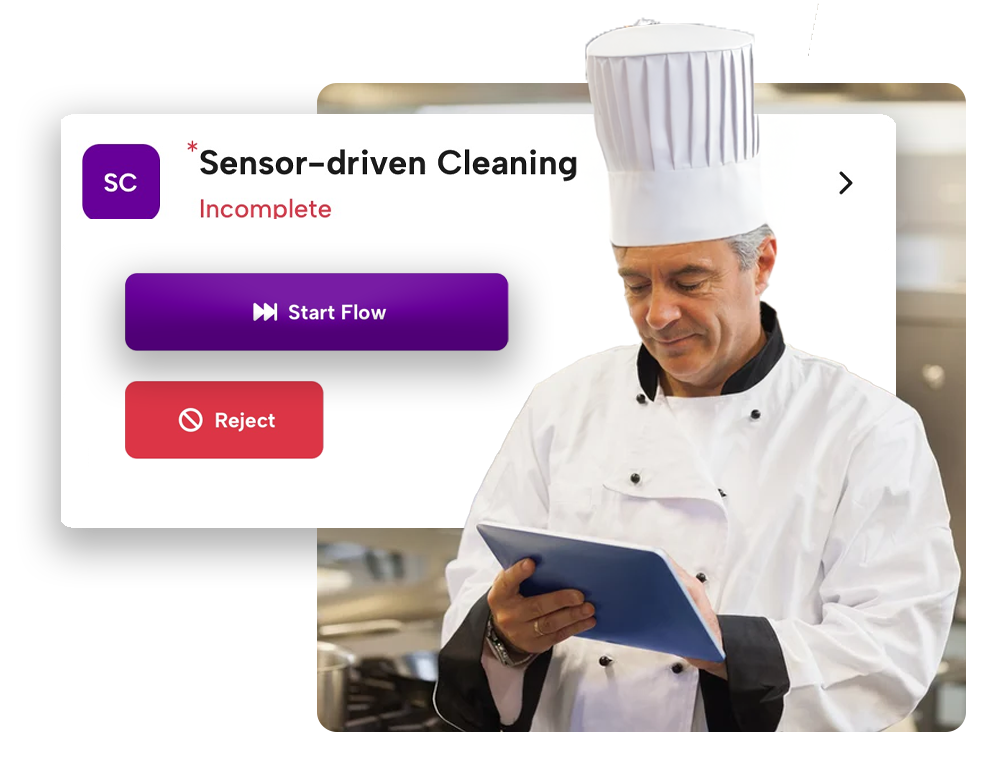

Automate Food Safety Monitoring

Streamline food safety processes with automated monitoring and reporting.

Learn More

Implement automated monitoring for critical control points (CCPs) to reduce the risk of human error. Automating these processes ensures consistent food safety practices and improves compliance with HACCP standards. Free up time for your team to focus on critical tasks by minimizing manual record-keeping and reporting efforts.

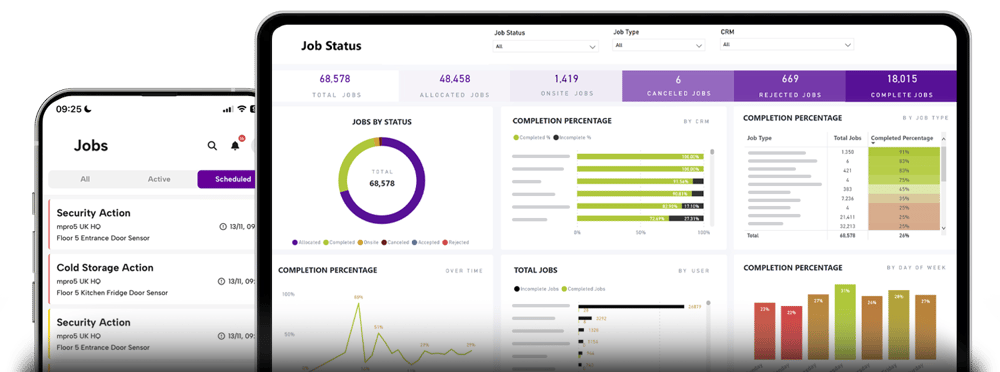

Gain Real-Time Food Safety Insights

Use data to anticipate potential risks and enhance food safety.

Learn More

Leverage real-time data analytics to identify trends, anomalies, and potential food safety risks. This proactive approach helps you address issues before they become critical, improving overall food safety and compliance. By using actionable data, you can continuously improve your food safety protocols.

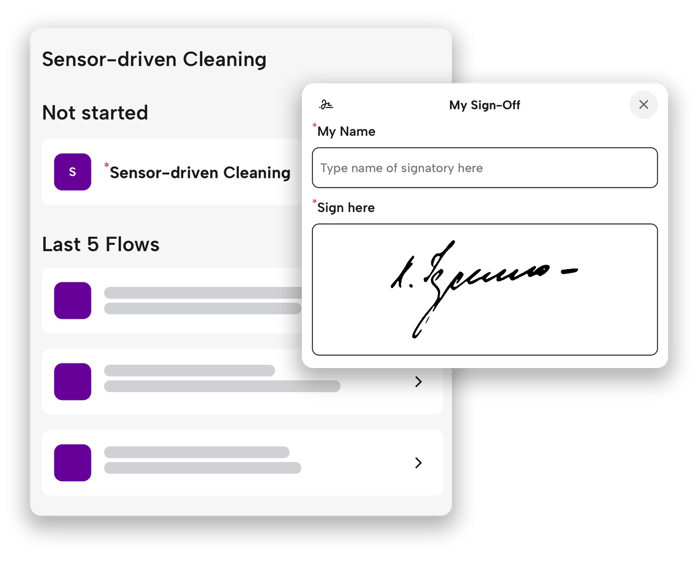

Centralize HACCP Documentation and Reporting

Streamline your HACCP records for quick access and audit-readiness.

Learn More%20Graphic.png?width=700&height=401&name=Quality%20Management%20(QMS)%20Graphic.png)

%20Graphic.png?width=1135&height=651&name=Quality%20Management%20(QMS)%20Graphic.png) Keep all HACCP documentation, including records for hazard analysis, control measures, and corrective actions, in one centralized digital platform. This ensures that your records are easy to access and audit-ready at all times, streamlining your compliance efforts and reducing the risk of errors.

Keep all HACCP documentation, including records for hazard analysis, control measures, and corrective actions, in one centralized digital platform. This ensures that your records are easy to access and audit-ready at all times, streamlining your compliance efforts and reducing the risk of errors.

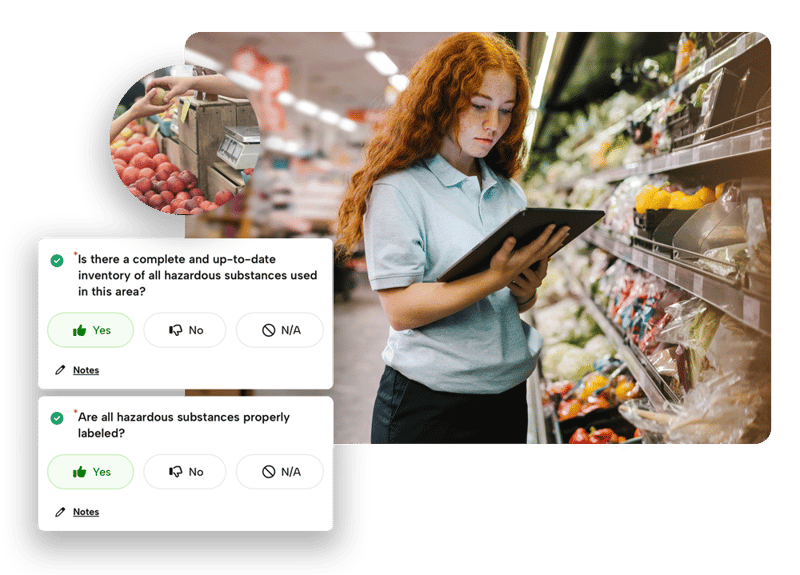

Remove Paper-Based Food Safety Processes

Digitize your HACCP workflows to reduce errors and inefficiencies.

Learn More

Move away from manual, paper-based food safety systems by adopting a fully digital HACCP solution. Digital records are more accurate, reduce the risk of data loss, and streamline the entire process. This leads to faster decision-making, more efficient reporting, and a stronger food safety culture across your team.

Move away from manual, paper-based food safety systems by adopting a fully digital HACCP solution. Digital records are more accurate, reduce the risk of data loss, and streamline the entire process. This leads to faster decision-making, more efficient reporting, and a stronger food safety culture across your team.

Start streamlining your processes today!

Complete the short form below and we'll be in touch soon!

43%

UK supermarkets using mpro5

140+

Million work orders completed

175+

Million jobs created

Explore All of our Food Safety Solutions:

Select an option below:

- QMS

- Food Safety Management

- Compliance

- Food Traceability

- Temperature Checks

- Operations Management

- OHS

QMS

Enhance quality management with our integrated QMS solutions. Drive consistency and continuous improvement across operations.

Food Safety Management

Simplify food safety management for compliance and quality. Protect your brand with the highest safety standards.

Temperature Checks

Streamline temperature monitoring for safety and compliance. Eliminate risks with automated, real-time automated logging.

Operations Management

Transform operations management with mpro5's intuitive solutions. Streamline workflows and drive operational excellence across your organization.

OHS

Protect your people and business with comprehensive OHS tools. Ensure compliance and foster a safe, productive environment.

Frequently Asked Questions

Find answers to common questions we receive.

-

What is HACCP?

HACCP stands for Hazard Analysis and Critical Control Points, a systematic approach to food safety management that identifies, evaluates, and controls food safety hazards. By identifying critical control points (CCPs) where hazards can occur, HACCP helps businesses prevent contamination and ensure safe food production.

-

Why is HACCP important in food safety?

HACCP is essential for preventing foodborne illness and ensuring that food products are safe for consumption. By focusing on critical control points in the food production process, HACCP helps businesses comply with food safety regulations, protect public health, and improve product quality.

-

How does HACCP work in food safety management?

HACCP works by identifying and analyzing potential hazards at each stage of the food production process. Once hazards are identified, critical control points (CCPs) are established, and monitoring systems are implemented to ensure food safety. Corrective actions are defined to address any deviations from safety standards, ensuring that food products remain safe from farm to table.

-

What are the benefits of using a digital HACCP system?

A digital HACCP system offers numerous advantages for food safety management, including:

- Enhanced Accuracy: Automate monitoring and data entry to reduce human error and improve compliance.

- Real-Time Monitoring: Access up-to-date data to proactively manage food safety risks before they escalate.

- Efficient Reporting: Easily generate reports and maintain records, ensuring you’re always audit-ready.

- Improved Decision-Making: With actionable insights from real-time data, make informed decisions to improve food safety processes and minimize risks.

-

How can HACCP compliance improve food safety in my business?

HACCP compliance can significantly enhance food safety in your business by:

- Reducing Risks: Identify and control food safety hazards before they cause harm.

- Improving Product Quality: Ensure that food products meet safety standards consistently, improving overall quality.

- Increasing Consumer Trust: Demonstrating your commitment to food safety helps build customer confidence and loyalty.

Our latest insights:

3 min read

Ensuring Compliance in the Food Industry: Strategies for Channel Partners and Industry Leaders

Dec 6, 2024 by Matt Smith

Businesses must ensure they are compliant with Natasha’s Law amid continued allergen woes

Dec 2, 2024 by Matt Smith

%20Graphic.png?width=288&height=165&name=Quality%20Management%20(QMS)%20Graphic.png)

%20Graphic.png?width=288&height=224&name=Occupational%20Health%20%26%20Safety%20(OHS)%20Graphic.png)